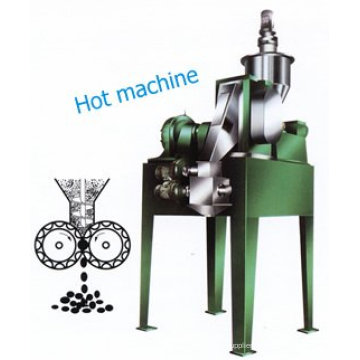

Walzenpressen Granulator

Basisinformation

Modell: GZL

Produktbeschreibung

| GZL Dry Roller Pressing Granulator |

|

Adopts dry pressing technology to pressure material with moisture content of lower than 10% into sheets, and it’s processed into required particles through breaking, granules treaming and screening process. The material is pressed by exterior force, and passes through the gap between the two rollers which are rotating in different directions, and then it's pressed into sheets. The mass density of material might increase 1.5-3 times, so to achieve required strength.

The material is forced and to be pressed by mechanical force, without any additional ingredients, so to ensure purity. The dry material is made into granules directly, no need any further drying process. So it's good for product process. The strength of the particles are high, the mass density is increased more apparently compare to other method of granulation. It's especially applicable for to increase the mass density of product. The pollution of environment is controlled, the wasted powder is reduced, the packaging fee is decreased and the product is easier in transportation. The structure is compact, the maintenance is convenient, the operation is simple, the process is short, the energy consumption is low, the efficiency is high, the probability of fault is low, the application range is wide, and the pressure of roller might be adjusted freely according to the property of material. The material feeding adopts non-step inverter control, the automation level is high. One operation high control muti-units of machine. The labor intensity is low, and the machine might run continuously in long time. Adopt high quality alloy, stainless steel, Ti, Cr and other metal for driving parts, the wear-resistance, cossive-resistance, thermo-resistance and pressure-resistance is highly increased. The service life is long.

Dry material powder is fed from the top of the equipment, de-air, screw-pre-press, enter into the gap between the two rollers that are rotating in opposite directions. The pressed material falls down because of surface tension and gravity when passes through pressing section. The noodles shaped material then enters into breaking machine, been smashed by rotating knife. The smashed material enters into granulator, and then the particles and part of powder material enters into sieve by the rolling knife, and then the product is separated. The product up to standard will be conveyed to product silo by conveyor; the material under the sieve should be fed back and should be pressed again. The pressure might adjust by the hydraulic oil cylinder according the requirements of granulation. Sheet, bar and other shape of product might be procured by choose the relative shape of the grooves on the surface of the roller.

The material enters into the hopper lifting machine through spiral conveyor from the feeding port, and then it's delivered to vibration material silo. A metered feeder will feed the material into inverter controlled spiral feeder, and the material is then pre-pressed. The pre-pressed material enters into the gap between the two rollers that are rotating in opposite directions, and then it's firmly pressed. The firmly pressing force is transferred to the material through the pushing force of oil cylinder. The firmly pressed material sheet falls into the breaking machine automatically, and been smashed into granules of different sizes, and then enters the granulator to be trimmed. The trimmed granules is squeezed out into the sieve through a mesh board. The final product enters into hopper lifting machine, and then it's conveyed to final product silo. The material sieved out should be fed back to the material silo by spiral conveyor, so to perform the next circulation. Hopper Lifting Machine Fine Power recycle Particle of product Grinding & Granulation device

Petro-chemical, fine chemical, pharmaceutical, foodstuff, metal powder, Bio-engineering, pesticide, fertilizer, mine and coal.

Produktgruppe : Trockener Granulator Premium Related Products andere Produkte

heiße Produkte YZG / FZG VakuumtrocknerYS Series Fluid Bett Hopper Hebemaschine (Hebemaschine)Vertikaler Fluidisierungstrockner im FutterJCT Serie Spezieller Ofen für PharmaGZQ Serie Rectilimear Vibrating-Fluidized Drier Maschine für die chemische IndustrieInstant lösliche Kapseln ProduktionslinieLebensmittelkörnchenherstellungsmaschine (Labor-TrockengranulatorKugelgranuliermaschine für die keramische IndustrieKleines Holzprodukt für Mesh-GürteltrocknerDLB-Wirbelbett-Dünger-Wirbelschichtbeschichtungsgerät zum Granulieren des MaterialsSZG Serie Konischer Staubsauger in Hefe verwendetLG Serie Rollenverdichter in Tablettenkapsel verwendetMini-Vakuum-GefriertrocknerIndien Graphen Vakuum TrocknerKalkstein-TrocknerMoringa Pulverblatt Trockenmaschine |